Introducing Predict: A Paradigm Shift in Digital Production Control from Rapid Granulator

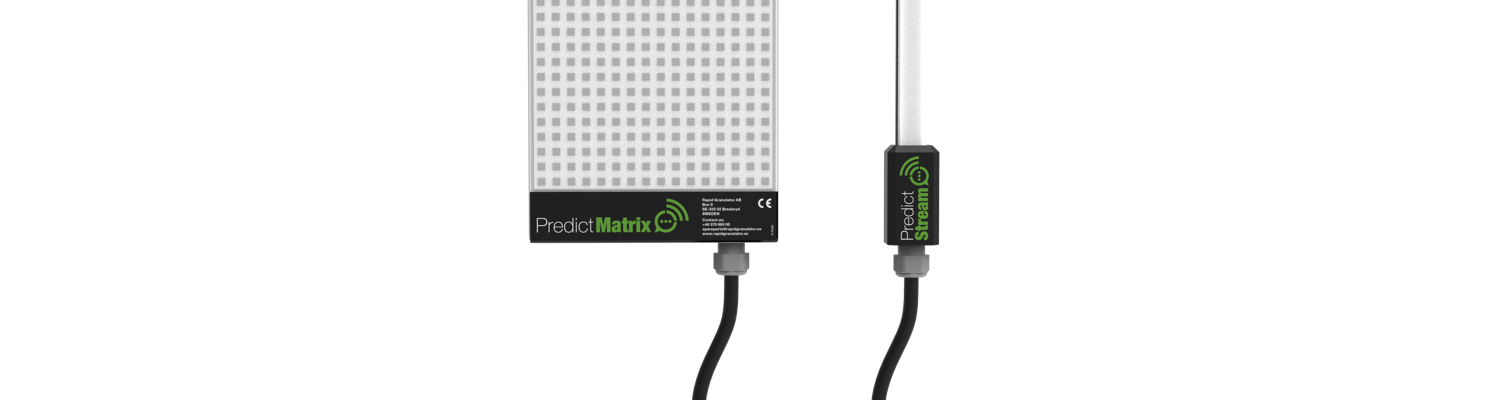

Bredaryd, Sweden, September 23, 2025 – Following the successful launch of Rapid Connect in 2022, Rapid Granulator is now taking a bold step forward in digital production monitoring with its latest innovation: Predict. Designed to work seamlessly with Rapid Connect, this advanced feature gives operators instant, crystal-clear insights into how their granulators are performing. Predict will be introduced for the first time at K 2025, held in Düsseldorf, Germany, October 8-15, Booth D10, Hall 9.

Real-time operational transparency at the point of production

Predict is meticulously engineered to streamline the daily responsibilities of operators. With the integration of Matrix and Stream LED displays (strategically mounted in proximity to the granulator) operators are provided with an immediate, straightforward, and real-time overview of machine performance. This helps them perform tasks such as material feeding, rapid operational adjustments, and energy-optimized performance improvements directly at the production source, thus accelerating the decision-making process.

Augmented operational efficiency and downtime mitigation

By synergizing the capabilities of Rapid Connect and Predict, production teams benefit from an unparalleled dual-layered framework: a comprehensive system overview coupled with localized, granular control for rapid and informed decision-making. This holistic visibility ensures that deviations from optimal performance are detected and rectified preemptively, thus preventing unanticipated disruptions in the production cycle. The result is a marked reduction in downtime, enhanced process fluidity, and smarter resource distribution.

Propelling profitability and environmental stewardship

Recycling machinery continues to be indispensable for both profitability and sustainability within the plastics production sector. By prioritizing energy consumption and operational uptime, Predict strengthens the Rapid Connect platform, so operators can leverage real-time responsiveness to keep equipment running at peak efficiency, minimize energy waste, and boost overall productivity.

“As our customers navigate the intricate challenges of modern production environments — from minimizing unscheduled downtime to optimizing energy usage and developing smarter production lines — Predict serves as an invaluable extension of Rapid Connect,” explains Anders Martensson, sales & marketing director at Rapid Group. “This solution enables operators to gain immediate visibility at the machine level, while also benefitting from Rapid Connect’s comprehensive system monitoring. Together, these innovations deliver a robust and forward-thinking approach to sustainable recycling.”

A versatile solution for wide-ranging compatibility

Versatile like Rapid Connect, Predict can be seamlessly integrated with both Rapid equipment and machinery from other manufacturers. Its straightforward installation process and intuitive user interface make it an accessible and flexible enhancement for plastics processors worldwide.

From Gut Feeling to Data-Driven Performance – Arla Plast Transformed Production with Rapid Connect

How efficiently is your equipment really being used? For Arla Plast AB, a leading producer...

Rapid Granulator Appoints Ingenieurbüro Dr. Brehm AG as Exclusive Sales Partner in Switzerland

Bredaryd, Sweden, September 24, 2025 – Rapid Granulator is proud to announce that Ingenieurbüro Dr....

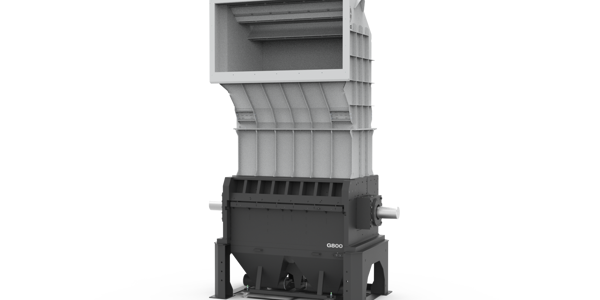

Rapid Granulator Unveils the 800 Series – The Largest and Safest Granulator in Its Class

Bredaryd, Sweden, September 23, 2025 – Rapid Granulator proudly introduces the 800 Series, marking the...