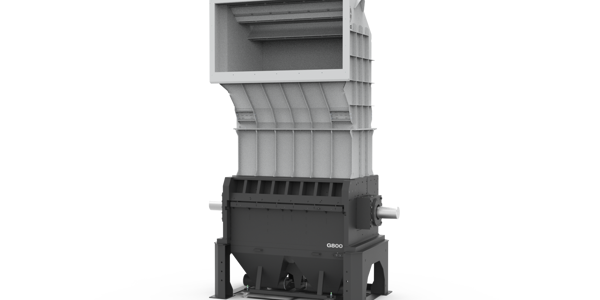

Rapid Granulator Expands Reputable GT Series with the Introduction of the GT1600 for Thermoforming Lines

Bredaryd, Sweden, September 23, 2025 – Rapid Granulator, a global leader in the manufacturing of plastic recycling solutions, is proud to unveil the expansion of its reputable GT series with the introduction of the GT1600. Specifically engineered to handle the wider skeletal waste streams generated in sheet and film thermoforming processes, the GT1600 enhances the capabilities of its predecessor, GT1100, expanding Rapid’s comprehensive portfolio of in-line granulation technologies. Both models will be on display at K 2025 in Düsseldorf, Germany, October 8-15, Booth D10, Hall 9.

Engineered for uninterrupted production excellence

The GT series demonstrates Rapid’s commitment to maximizing operational uptime. With a design that allows for seamless, one-side access to all critical wear components, both maintenance and cleaning procedures are streamlined, enabling faster and safer intervention. This unique feature ensures that production lines remain in optimal, continuous operation — critical for thermoforming manufacturers, where every moment of downtime equates to significant cost and resource loss.

“We work closely with customers and machine operators to ensure our innovations meet real-world demands,” says Anders Mårtensson, sales & marketing director at Rapid Granulator. “The need for wider, more efficient granulation solutions has been a clear and resounding request. With the GT1600, we now offer a machine that combines exceptional capacity, robust reliability, and operational ease, engineered to meet the exact needs of today’s thermoforming market.”

Lower operational costs, elevated material utilization

For thermoforming manufacturers, skeletal waste represents a substantial portion of raw material consumption. The GT1600 is purpose-built to efficiently reprocess this waste, converting it into high-quality regrind that can be seamlessly reintegrated into production. This reduction in material waste not only enhances resource efficiency but also directly drives profitability through lowered operational costs.

Designed for adaptability and next-generation performance

True to Rapid’s reputation for innovation, the GT1600 is built with a modular design that offers unparalleled flexibility. It can be seamlessly integrated into diverse thermoforming line configurations, irrespective of material flow direction or setup. This makes the GT1600 a smart investment that is adaptable to evolving production requirements, ensuring long-term operational excellence and scalability across a range of production environments.

From Gut Feeling to Data-Driven Performance – Arla Plast Transformed Production with Rapid Connect

How efficiently is your equipment really being used? For Arla Plast AB, a leading producer...

Rapid Granulator Appoints Ingenieurbüro Dr. Brehm AG as Exclusive Sales Partner in Switzerland

Bredaryd, Sweden, September 24, 2025 – Rapid Granulator is proud to announce that Ingenieurbüro Dr....

Rapid Granulator Unveils the 800 Series – The Largest and Safest Granulator in Its Class

Bredaryd, Sweden, September 23, 2025 – Rapid Granulator proudly introduces the 800 Series, marking the...