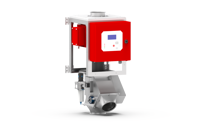

Rapid Granulator Launches RMD (Rapid Metal Detection) – Instant Protection for Slow-Speed Granulators

Bredaryd, Sweden, September 23, 2025 – Rapid Granulator introduces RMD (Rapid Metal Detection), a breakthrough safety solution designed specifically for slow-speed granulators. The system instantly halts the rotor the moment metal is detected, safeguarding the critical interface between fixed and rotating knives, without interrupting production. Experience RMD live at K 2025, October 8-15 in Düsseldorf, Germany, Booth D10, Hall 9.

Seamless, integrated protection

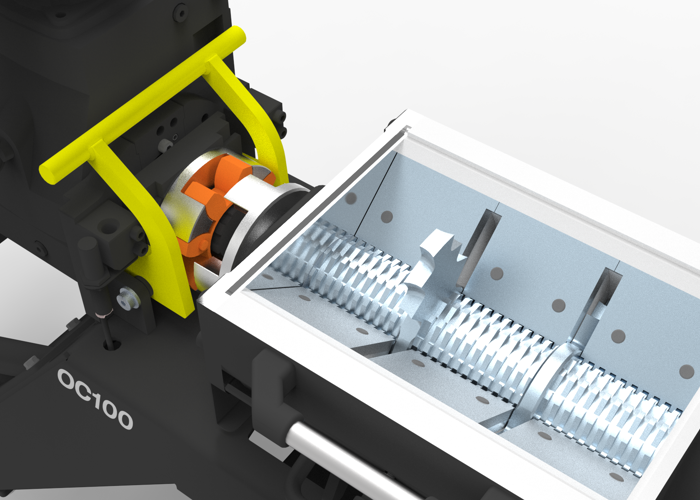

RMD is fully integrated into the granulator, remaining completely hidden and non-intrusive. Unlike conventional metal detectors, it protects precisely where it matters most — before any contaminants reach the cutting chamber.

Immediate response, maximum protection

Even the smallest piece of metal triggers an instant rotor stop. This solution prevents costly damage to the rotor and knives while minimizing downtime and maintaining process continuity.

Reliable across all materials

Equipped with high-sensitivity sensors, RMD detects all types of metals and other conductive contaminants. It provides consistent, dependable protection across a wide range of recycling and processing applications.

Smarter safety, greater efficiency

With instant detection and response, RMD reduces maintenance costs, extends equipment life, and enhances overall production safety and efficiency.

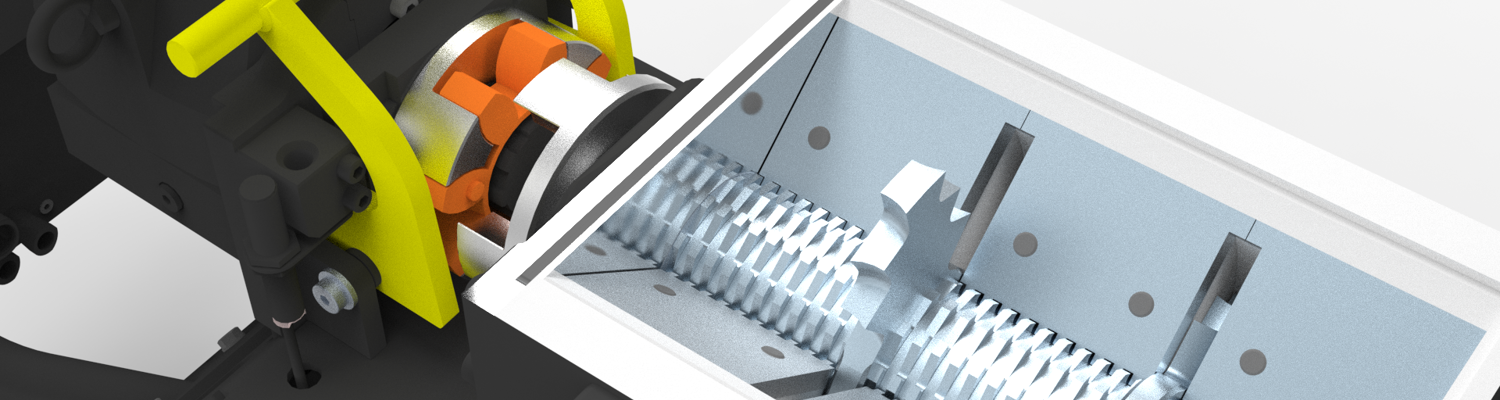

Reliable detection, maximum protection

RMD’s rotor design enabling highly reliable metal detection. Even the smallest piece of metal triggers an instant rotor stop, preventing costly damage to both rotor and knives while minimizing downtime.

Flexible operation with standard knives

Unlike many competitor solutions, RMD allows the use of standard knives, providing operators with unmatched operational flexibility and simplifying maintenance.

“RMD sets a new benchmark in granulator safety,” says Anders Martensson, sales & market director at Rapid Group. “By protecting the knife interface instantly and ensuring it is non-intrusive, operators can avoid costly damage and maintain peak production performance.”

From Gut Feeling to Data-Driven Performance – Arla Plast Transformed Production with Rapid Connect

How efficiently is your equipment really being used? For Arla Plast AB, a leading producer...

Rapid Granulator Appoints Ingenieurbüro Dr. Brehm AG as Exclusive Sales Partner in Switzerland

Bredaryd, Sweden, September 24, 2025 – Rapid Granulator is proud to announce that Ingenieurbüro Dr....

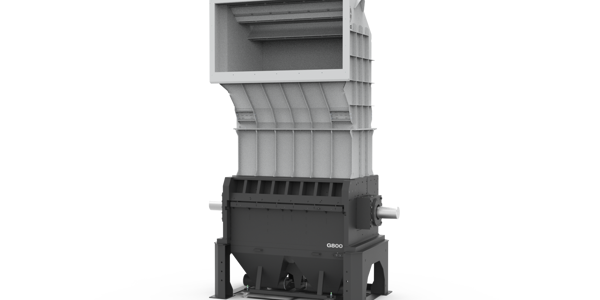

Rapid Granulator Unveils the 800 Series – The Largest and Safest Granulator in Its Class

Bredaryd, Sweden, September 23, 2025 – Rapid Granulator proudly introduces the 800 Series, marking the...