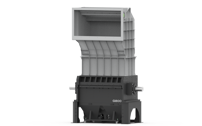

Rapid 800 Series is engineered for high-volume granulation, making it ideal for both central and in-line processing of large products. With a robust construction and advanced cutting technology, it combines reliable performance with safe, efficient maintenance. The series is also optimized for wet granulation applications.

Granulators

800 Series

-

Safe and smart maintenance

- Designed for quick, secure, and user-friendly servicing. Every detail is engineered to minimize downtime, reduce risks, and simplify the work process, ensuring that maintenance can be carried out efficiently.

-

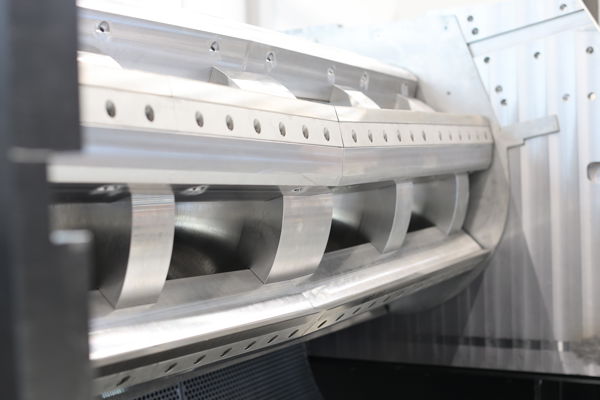

Patented knife holder system

- Our patented knife holder system, allowing safe and fast knife changes from outside the granulator. This reduces physical strain, shortens service stops, lowers maintenance costs, and enhances safety – without compromising cutting precision or performance.

-

Pre-adjustable knives

- With a fixture, presetting the knives outside the machine is easy, providing fast and convenient servicing. The optional grinding fixture makes resharpening of knives easy and guarantees the correct knife angles.

-

High quality regrind

- The Rapid cutting technique, comprised of clean scissors-cutting action and constant cutting circle, produces granules of a uniform size with minimal dust content even with the toughest materials.

Rapid 800 Series is engineered for high-volume granulation, making it ideal for both central and in-line processing of large products. With a robust construction and advanced cutting technology, it combines reliable performance with safe, efficient maintenance. The series is also optimized for wet granulation applications.

Patented knife holder system

The 800 Series features our patented knife holder system, allowing safe and fast knife changes from outside the granulator. This reduces physical strain, shortens service stops, lowers maintenance costs, and enhances safety – without compromising cutting precision or performance.

Scissors cut for efficient cutting

Scissor cut technology ensures efficient, energy-saving cutting with less wear, providing consistent, precise results while reducing maintenance needs. This advanced design not only enhances performance over time but also improves overall reliability, making it ideal for both frequent and demanding use.

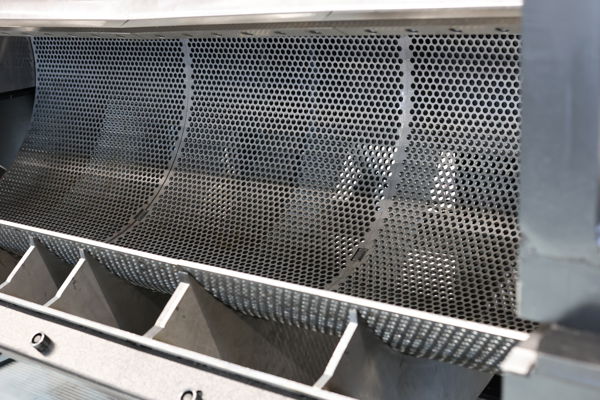

Reversible screen

Most granulation or cutting occurs at the screen surface. Hence it is extremely important to have the screen in good condition. A worn screen gets rounded hole edges and needs to be replaced with a new screen. Screens from Rapid are reversible (excluding special screens) which gives them double the life.

Specifications

| Model | 800 | |

| Rotor diameter | mm | 800 |

| Rotor type | 6-blade Beam | |

| Rotating knives | 24 (6x4) | |

| Fixed knives | 8 (2x4) | |

| Cutterhouse Tagential / Pre cut (Optional) | mm | 2000x800 |

| Motor (Standard) | kW | 132 |

| Motor (Optional) | kW | 110 / 160 / 200 / 250 / 315 |

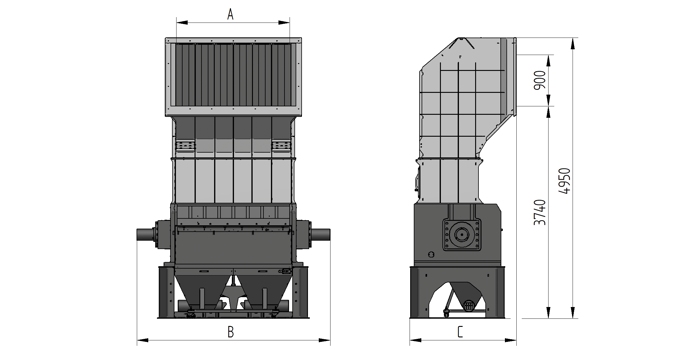

Dimensional drawing/layout

| 800 | ||

| A | mm | 2000 |

| B | mm | 3500 |

| C | mm | 1900 |