No matter how efficient a granulator is, there will always be a small amount of dust and fines – increasing when knives start to wear out. With an efficient and adapted dust separation system, these problems can be avoided. Rapid offers complete systems for all dust separation needs.

- Sharp knives are always good for minimizing the amount of dust.

- An efficient dust separation system filters out dust and fine particles and you get a high-quality granule to add back to your process.

- In addition to a better granule quality, the working environment will also be cleaner and safer.

Positive pressure system

- Rapid DS-50 up to 250 kg/h

- Rapid DS-400 up to 500 kg/h

- Rapid DS-800 up to 1,000 kg/h

Negative pressure system

- NPDS 500 with a capacity of up to 500 kg/h

- NPDS 1500 with a capacity of up to 1,500 kg/h

Assessories

Dust separation

No matter how efficient a granulator is, there will always be a small amount of dust and fines – increasing when knives start to wear out. With an efficient and adapted dust separation system, these problems can be avoided. Rapid offers complete systems for all dust separation needs.

- Sharp knives are always good for minimizing the amount of dust.

- An efficient dust separation system filters out dust and fine particles and you get a high-quality granule to add back to your process.

- In addition to a better granule quality, the working environment will also be cleaner and safer.

Positive pressure system

- Rapid DS-50 up to 250 kg/h

- Rapid DS-400 up to 500 kg/h

- Rapid DS-800 up to 1,000 kg/h

Negative pressure system

- NPDS 500 with a capacity of up to 500 kg/h

- NPDS 1500 with a capacity of up to 1,500 kg/h

Increase your Productivity and Profitability

By minimizing dust and fine particles in the output from your granulators, you reduce the loss of valuable raw material. In addition, you reduce the rejections due to imperfections caused by burnt dust particles in the material.

The most common cause of dust formation is worn knives in the granulator that need sharpening/replacement. Worn screens also increase dust formation.

Positive Pressure System

This traditional type of dust separation system works by having the granulator connected to a fan that blows material into a cyclone. Under the cyclone, a dust separation system is mounted where dust particles are separated from the material. The size of the particles that are separated can be easily adjusted according to need/material.

In the picture below, the Rapid DS-400 Dust Separation System is connected to a Rapid 400 series granulator.

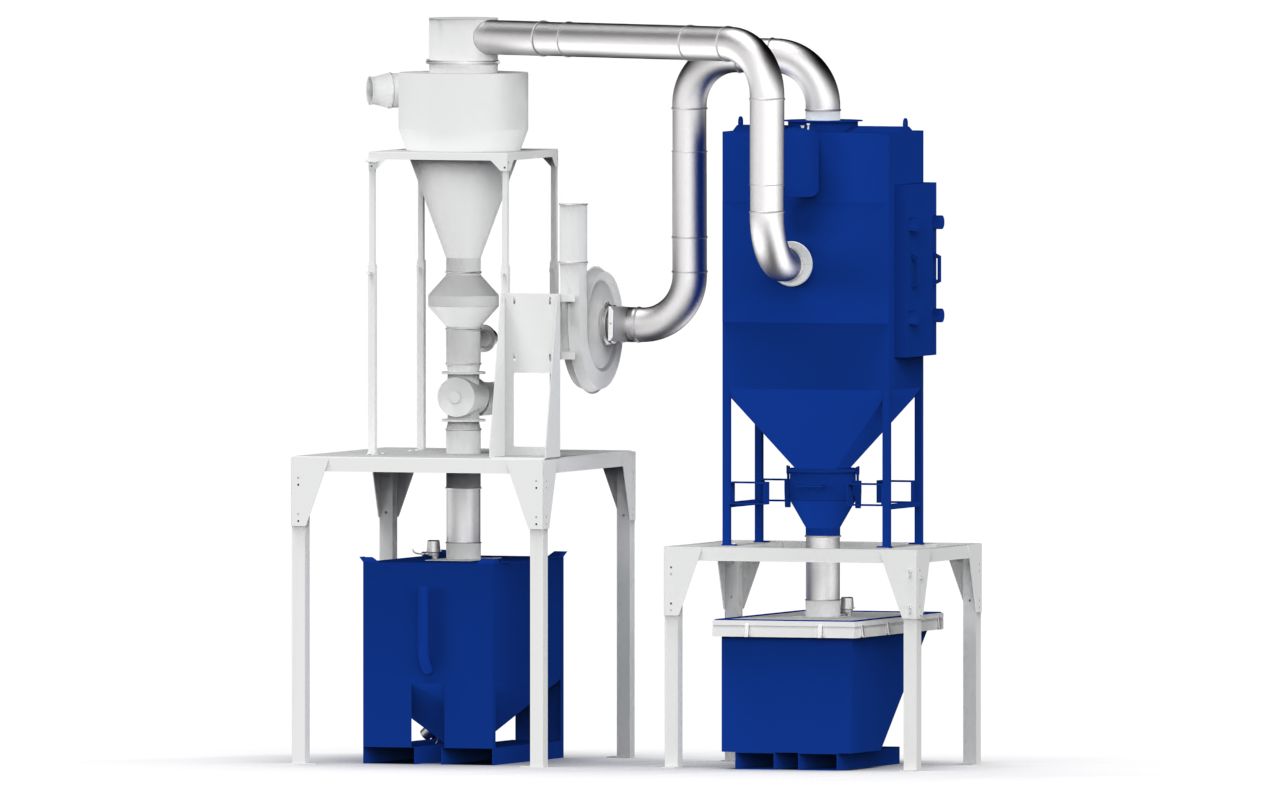

Negative Pressure System

This method is a high-efficiency solution for sensitive environments. In negative pressure systems, a fan is installed last in the system that creates negative pressure through granulator, pipeline, cyclone and dust separator.

The main advantages are that there is no risk of leakage in the transport line and this provides a better working environment. BIA Class M can easily be achieved with a central filter (see picture).